About Us

Our Businesses

Investors

Responsibility

Media

Careers

AB Agri takes pride in its heritage and track record of sourcing ingredients for animal feed that would otherwise go to waste, reducing the use of primary products.

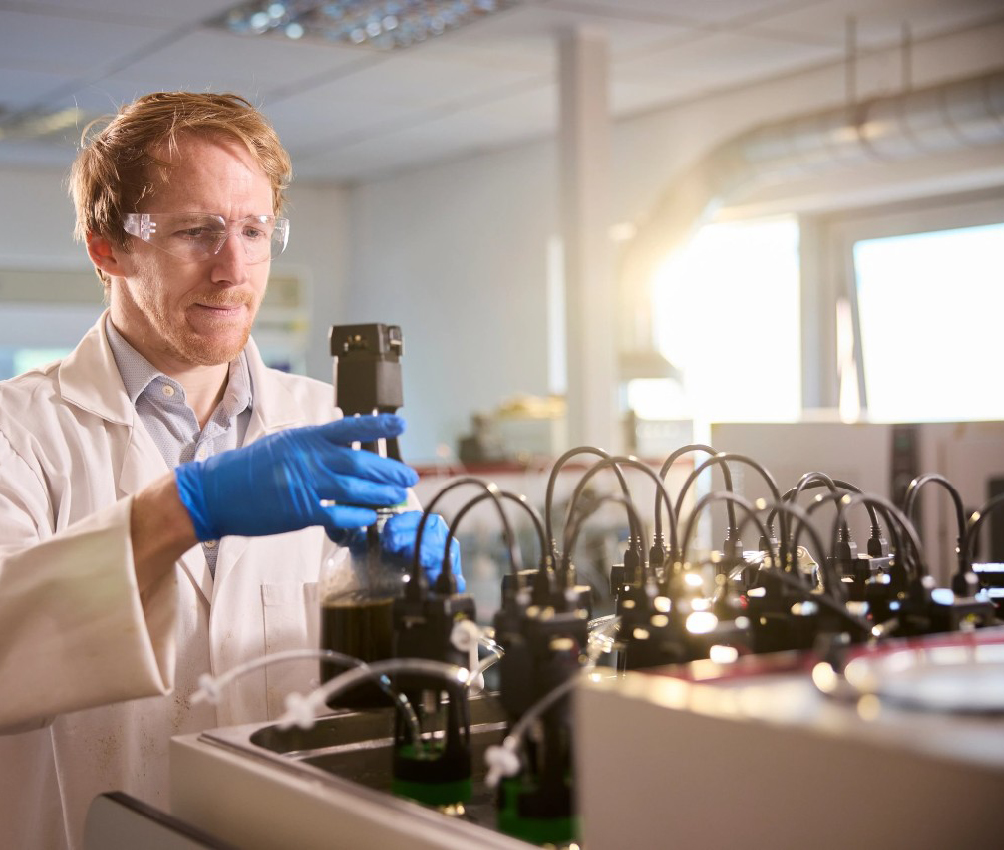

Testing the gas-yield potential of waste for use as anaerobic digestion feedstock at Amur Energy’s lab in York, UK

Testing the gas-yield potential of waste for use as anaerobic digestion feedstock at Amur Energy’s lab in York, UK

AB Agri contributes to more responsible and efficient resource use in agriculture. Its nutritional expertise supports the optimal use of various food co-products, such as the fibre-rich pulp from sugar beet production and the nutritious grains left over from brewing beer and whisky. Any co-products and food waste not suitable for animal feed are used to generate bio-energy through its specialist anaerobic digestion business, Amur.

In 2025, AB Agri’s total waste increased by 25% from 6.3kt in 2024 to 7.8kt. Of this waste, 92% was recycled or sent for reuse, with less than 0.6kt being sent to landfill. The increase was primarily due to commissioning a new software system at one of its sites. To ensure feed safety during the transition, additional flush batches were produced, temporarily increasing waste. This material was diverted to a local anaerobic digestion plant, where it was used to produce biogas. The software has now been fully commissioned and operations have returned to normal waste levels.

| 2021 | 2022 | 2023 | 2024 | 2025 | |

|---|---|---|---|---|---|

| Waste Generated | 7 | 6 | 5 | 6 | 8 |

| Waste Recycled | 89% | 89% | 91% | 87% | 92% |

At AB Agri, the use of plastic packaging for finished goods is low with most of its products being delivered as bulk. There are some businesses where it is more significant, due to the nature of the products and services being offered, in particular at Global Supplements and National Milk Records (NMR).

AB Agri remains committed to eliminating, reducing or redesigning the packaging it uses for its products. It has successfully conducted trials aimed at transitioning towards using recycled content plastic packaging. Changes have been implemented across some of its UK businesses, such as using recycled materials in shrink wrap, tote bags and plastic tubs within Premier Nutrition's equine range.

AB Agri continues to map its packaging data to build a more detailed understanding of its packaging usage, focusing on the identification of opportunities for improvement. This analysis has helped to set internal targets at business unit level, aimed at reducing overall packaging use and increasing the volume of recycled plastic content.

In 2025, AB Agri used 6.6kt of packaging, a 9% increase compared to 2024, due to the introduction of new product lines requiring different packaging materials.

EDITOR NOTE:

This is the modal area for the above carousel. Please be careful when copying this to UAT or PROD. It would be best to include Cian in these movements. The carousel above has buttons which have ID tags which open the below containers. Be careful to maintain the ID tags.

AB Agri’s anaerobic digestion (AD) business, Amur, helps AD operators increase biogas production through performance products, feedstocks and technical advice. By maximising value from raw materials that would otherwise go to waste, Amur contributes to waste reduction and reuse, as well as reducing reliance on fossil fuels.

Amur continues to invest in developing new products to increase biogas production and replace the minerals and additives that are currently used with materials that have a lower environmental footprint. One example is the ADFe additive, an iron hydroxide-rich material sourced from disused coal mines in partnership with the British Coal Authority. ADFe is a recovered material and has a lower carbon footprint compared to other similar dry materials such as Iron Hydroxide, as it is dried naturally in the sun rather than through energy-intensive methods. Iron hydroxide is an essential additive needed to manage hydrogen sulphide levels in biogas facilities. In trials, ADFe has been shown to be 30% more effective than conventional products.

Colleague testing feedstock sample at Amur Energy lab in York, UK

In 2021, AB Agri’s business, Premier Nutrition, undertook a project to find and implement more sustainable packaging solutions for its equine product range. The project initially focused on a pilot with its largest equine customer.

During a comprehensive review of all packaging product lines, it was discovered that 40% of the plastic packaging used was in the form of plastic tubs and lids. The business worked with its supplier to successfully trial and implement an alternative, with 30% recycled plastic content, leading to a significant reduction in the use of new plastic.

The success of this project inspired Premier Nutrition to explore other opportunities for improvement, resulting in 30% recycled content now being used in other types of packaging, such as tote bags and shrink wrap. This positive change extended beyond its Premier Nutrition business, benefitting other AB Agri businesses as well. The knowledge and experience gained from this initiative has led to ongoing trials on plastic bags, which constitute the majority of packaging used across AB Agri.

Packaging product at our manufacturing site in Staffordshire, UK